The rejected materials are sent back by the Production Supervisor to the Stores and the rejected materials are disposed off as scrap. Check-on quality control equipments. The equipments are periodically checked and calibrated.

Preparation of Documents Purchasing.

Sampling Plans Production Instructions.

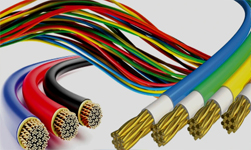

Inspection and Testing of Raw Materials.

Production on Process Finished Products.

To attend to Complaints Inspection Agencies.

Disposal of Rejected Materials.

Ashoka Industries

Ashoka Industries