Multi Conductor Braided Shield

These types of cables can be manufactured in Multipair with different size of Conductor also depends upon the Customer's requirement that is Individually PAIR Shielded with Poly AL or Braided and Overall Shield of the same type. These types of cables may be Armoured or Unarmoured. In the case of Armoured cable, inner Jacket of PVC/PVC tape is provided below the Armouring.

Product Description 24 AWG 7/32

Stranded Tinned Copper PVC insulated cores laid up Melinex Taped Tinned

Copper braided Shield and PVC Jacketed (Temp. Range -20C to +80°C)

Shielded Control & Data Cables

These types of cables can be manufactured in Multipair with different size of Conductor also depends upon the Customer's requirement that is Individually PAIR Shielded with Poly AL or Braided and Overall Shield of the same type. These types of cables may be Armoured or Unarmoured. In the case of Armoured cable, inner Jacket of PVC/PVC tape is provided below the Armouring.

Indivisualy Shielded Pair Cables

Product Description: 22 AWG Tinned Copper, PVC insulated, twisted Pairs, each pair and its Drain Wire under Poly Aluminium Shield, overall PVC Jacketed.

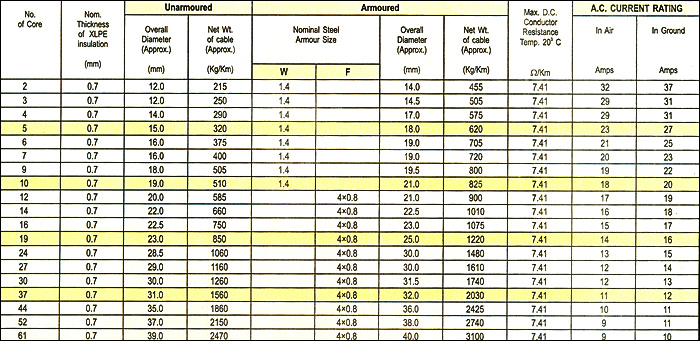

XLPE Insulated Heavy Duty Cables

Cross linked polyethylene (XLPE) is a thermosetting material obtained by forming cross linkages in polyethylene molecules. In the past two decades PVC had been the preferred material for insulating cables. It combined case of processing had good Electrical Properties and was economical. However, it suffered from inherent disadvantages because of its thermoplastic nature. This restricted the maximum operating temperature of the conductor and ability to withstand thermal overloads. It also had higher dielectric loss which makes its use economical in cables.

> Higher current rating

> Higher short circuit rating (approx. 1.2 times than PVC).

> Higher insulation resistance (1000 times more than PVC insulating cables).

> Higher resistance to moisture (1000 times more than PVC).

> Better resistance to surge currents.

> Has better resistance to most chemicals, oils and acids etc.

> Low dielectric losses.

> Better resistance to chemicals and corrosive gases etc.

> Comparatively higher cable operating temperature 90°C and short circuit temperature 250° Smaller bending radius longer service life.

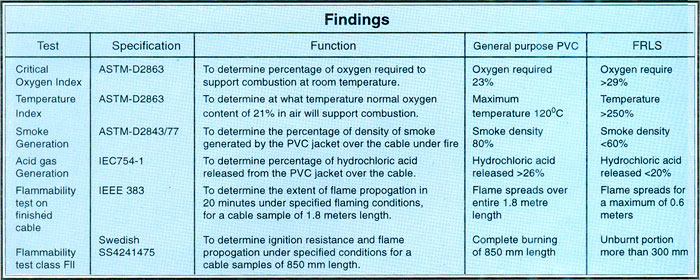

Flame Retardant Low Smoke Cables

Conventional power cables, control cables and house wiring cables, jacketed with PVC, although adequate for normal working conditions, prove hazardous in a high temperature environment, when exposed to fire from an external source. In installations such as power plants, steel plants, fertilizer and petrochemical plants, industries, high rise buildings, cinema theatres, hotels and hospitals, cables are grouped closely together in limited space and installed in ducts or racks. Fire from an external source spreads rapidly in such conditions causing enormous damage.

In addition to the danger of fire spreading rapidly, the dense black smoke generated lowers visibility, hindering fire fighting and rescue operations. Acidic fumes released by the fire are corrosive, causing great damage to sensitive electrical and electronic equipment.

Ashocab now introduces its range of Flame Retardant Low Smoke jacketed cables to counteract these hazards of conventional PVC cables. Ashocab has been a leading manufacturer of wires and cable sand enjoys an enviable eputation for the quality and reliability of its products.

> High resistance to ignition.

> High resistance to flame propogation.

> Low smoke emission.

> Low emission of acid fume.

> High critical oxygen index much greater than general purpose PVC.

> High temperature index-250°C as against 120°C for general purpose PVC.

> As a result, in the event of fire from an external source, FRLS cables arrest the spread of the flames, emit little smoke thus not impairing visibility and corrosive acid generation is minimized.

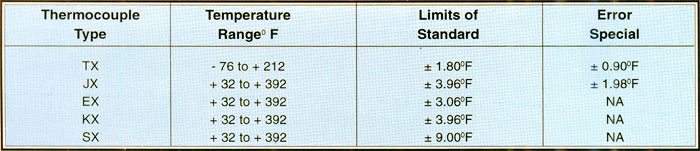

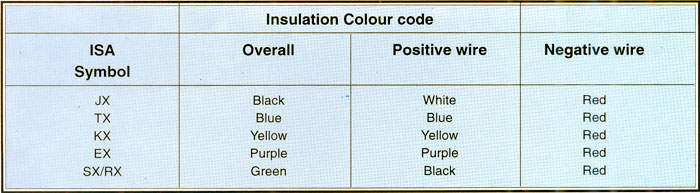

Thermocouple Wire And Cables

Ashoka Thermocouple Extension wire/cables are used to economically extend thermocouples to instrumentation in installation where thermocouple wire cost will be exorbitant. High accuracy is maintained by proper selection of wire material and insulating it to meet the field conditions where these wires/cables are installed. Every wire/cable is colour coded as per ISA and ANSI standards for quick identification. The wire/cables confirm to IS, ISA and ANSI recommended limits of error.

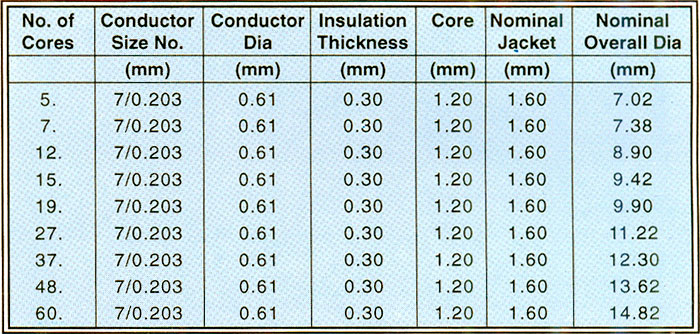

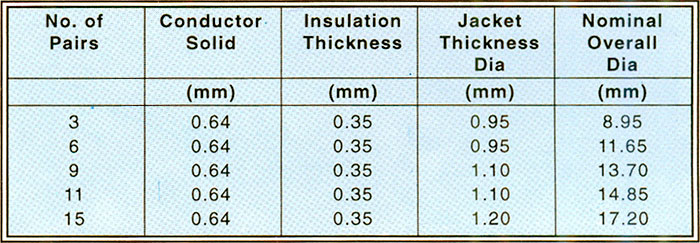

Instrumentation Cable

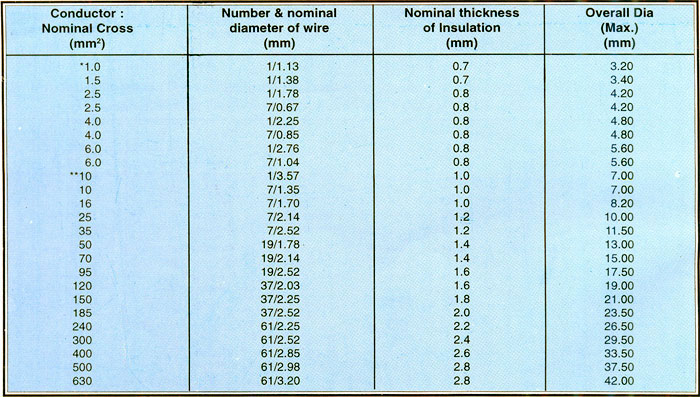

PVC Insulated Cables

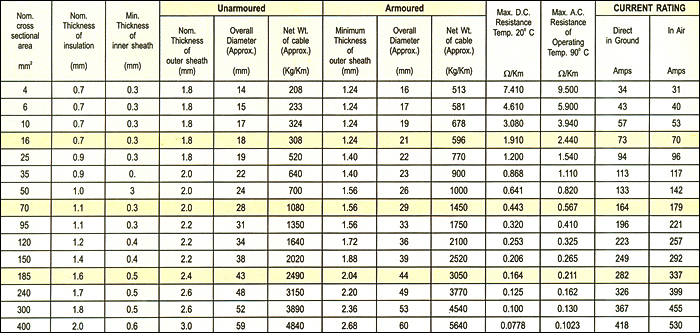

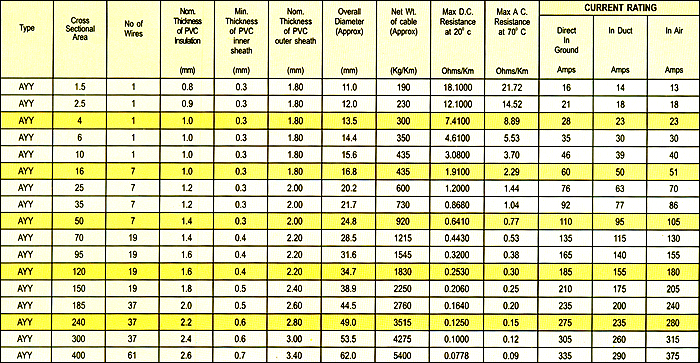

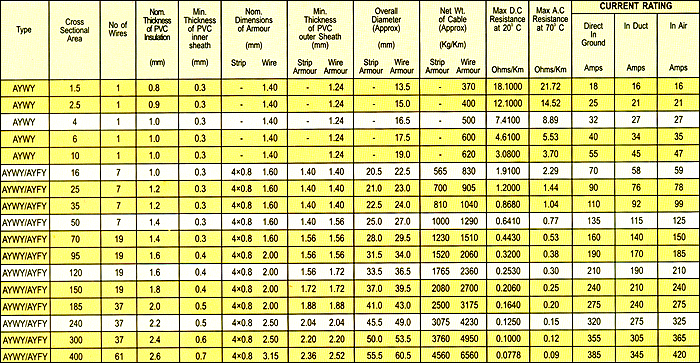

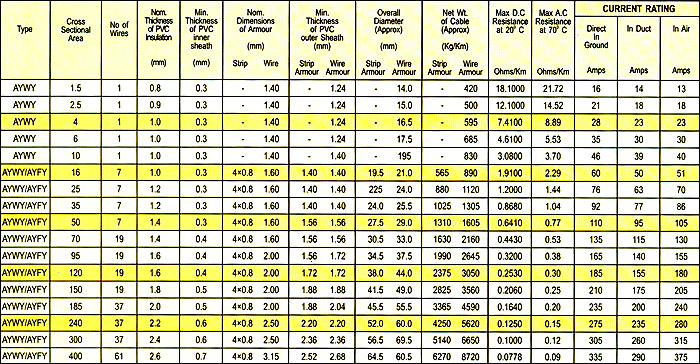

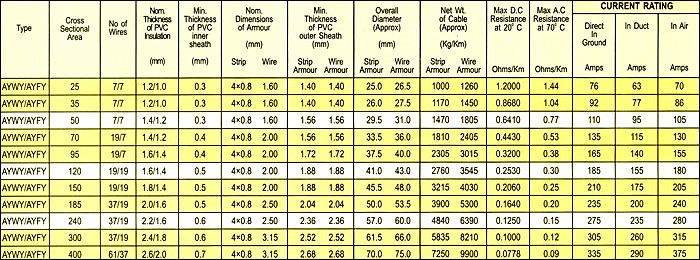

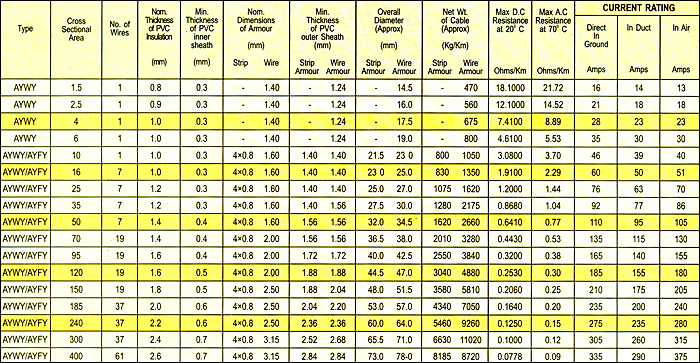

Single Core Aluminium PVC Armoured Power Cables IS : 1554 (Pt-1)1988

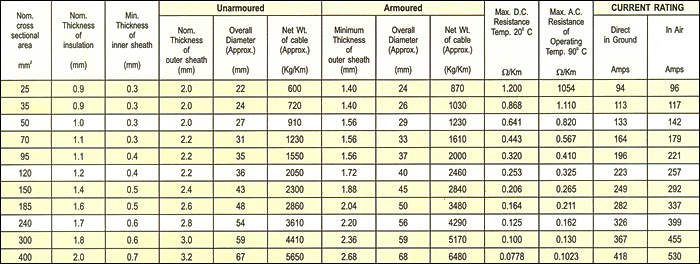

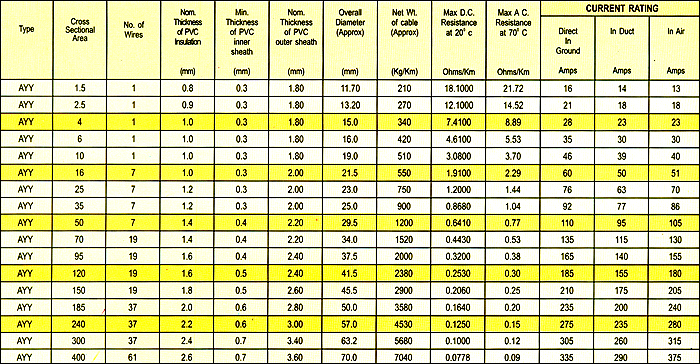

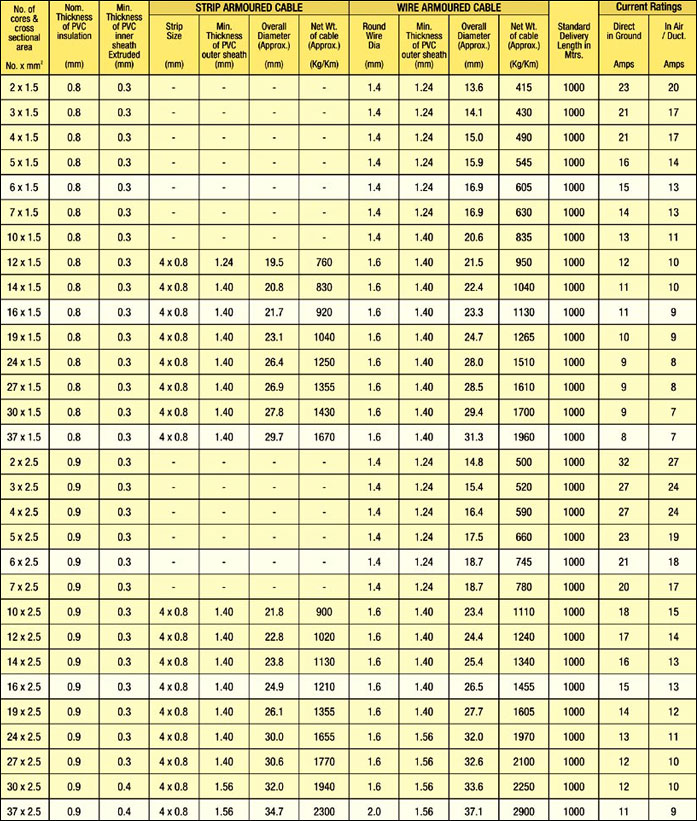

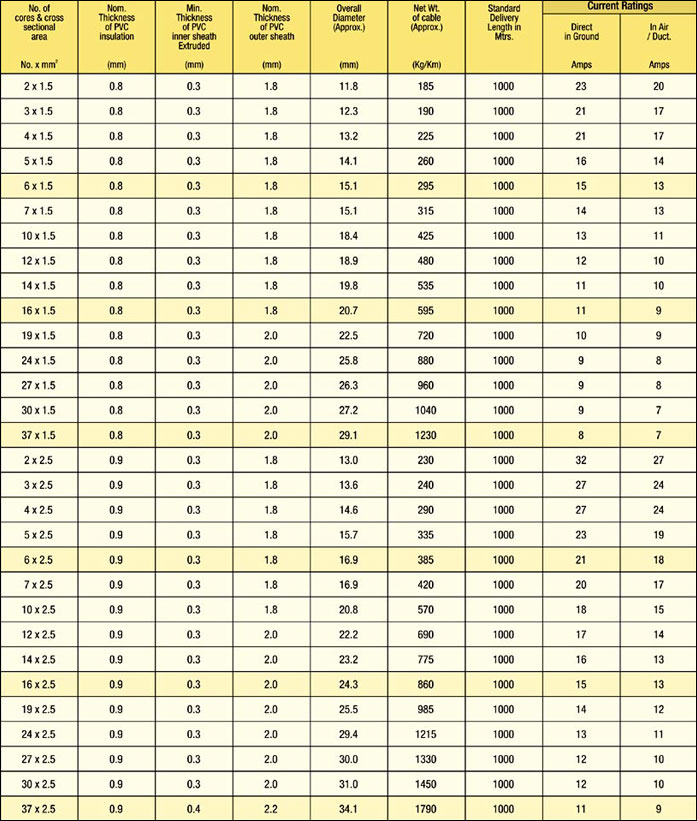

2 Core Aluminium PVC Armoured Power Cables IS : 1554 (Pt-1)1988

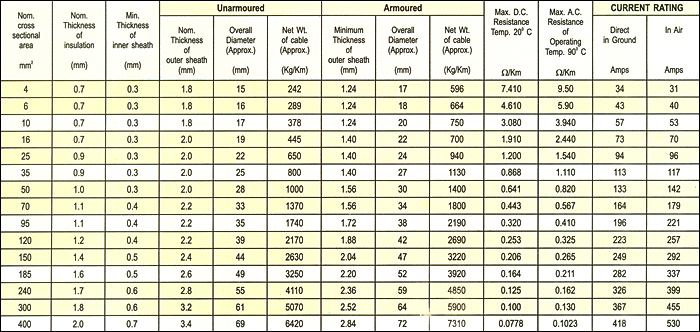

3 Core Aluminium PVC Armoured Power Cables IS : 1554 (Pt-1)1988

3.5 Core Aluminium PVC Armoured Power Cables IS : 1554 (Pt-1)1988

4 Core Aluminium PVC Armoured Power Cables IS : 1554 (Pt-1)1988

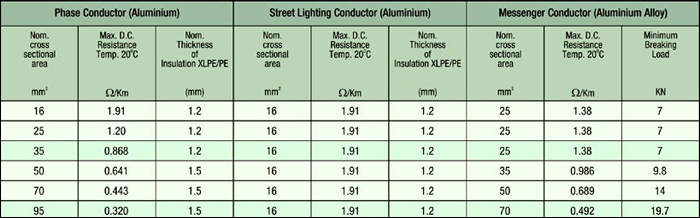

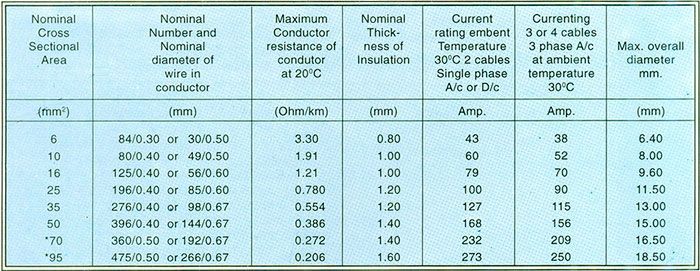

Aerial Bunched Cables

Aerial Bunched Cable (ABC) are a very naval concept for overhead power Distribution. When compared to the conventional bare conductor overhead distribution system, ABC provides higher maintenance and operative cost. This system is ideal for rural distribution and specially attractive for installation difficult terrains such as hilly areas, forest areas; coastal areas etc .These cables are being designed. Manufactured & tested conforming to IS: 14255 & other international specifications. ABC is also considered to be the choice for power distribution in congested urban areas with narrow lanes and by-lanes. In developing urban complex, ABC is the better choice because of flexibility for re routing as demanded by changes in urban development plan.

ABC can be conveniently used :

> As replacement of bare lines n Rural areas, in woods and in other localities & narrow streets where the space is limited.

> As replacement of bare lines where reliability of supply is of prime importance.

> As replacement of bare lines where high degree of stability of supply voltage is of importance.

> In hilly terrains where cost of erection of overhead lines or underground cable becomes very high.

> As reinforcement of existing system without increasing voltage.

> For temporary supplies.

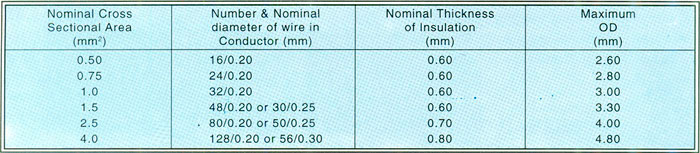

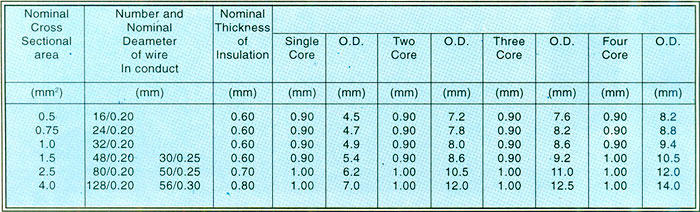

Domestic Wire

Conductor: Plain annealed high conductivity copper conductor to IS: 8130

Insulation: PVC Type A of IS:5831 (High insulation resistance values)

Specification: IS:694

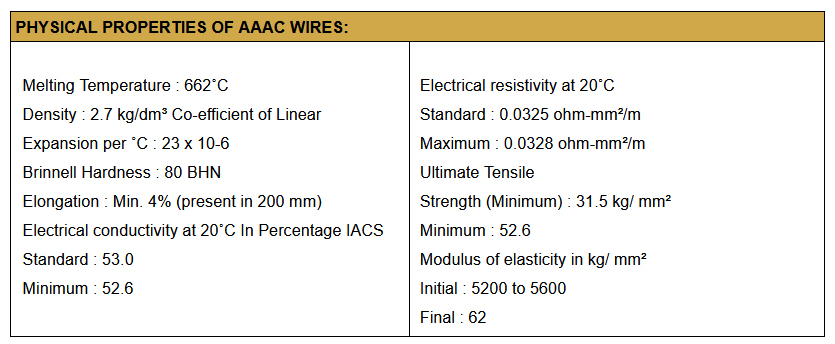

AAA Conductor

AAAC, which has been in use for several decades abroad, has been adopted now in India as well. The alloy is based on Aluminum - Magnesium - Silicon System (Al-Mg-Si). Aluminum Alloy Conductor is a generic name rather than the name of a particular conductor.

The group generally includes :

AAAC - High strength comprising heat treatable aluminum alloy wires.

AAAC - High Conductivity comprising of heat treatable aluminum alloy wires.

Aluminum Conductor Alloy Reinforced comprising of EC grade aluminum wires and high strength aluminum alloy wires with adequate conductivity.

Aerially Bunched Conductors comprising of compacted, bare-insulated, high strength aluminum alloy conductor as neutral messenger wire bunched with three to five insulated EC grade aluminum phase conductors and lighting conductors.

> High Tensile Strength as compared to AAC Conductor.

> Higher Conductivity as compared to ACSR Conductor.

> Better Corrosion resistant than ACSR Conductor.

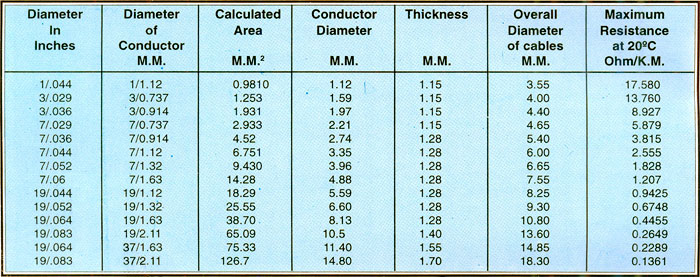

ACSR Conductor

Aluminium Conductors Steel Reinforced (ACSR conductors), as their name suggests, consist of a solid or stranded steel core surrounded by strands of Electrolytic grade aluminium. The steel core imparts high mechanical strength to ACSR conductors, which are therefore suitable to be used for river crossings, overhead transmission lines, installations involving extra long spans etc. For any given resistance, ACSR conductors can be manufactured having a wide range of tensile strength as per customer requirements. The principal advantages of these conductors are high tensile strength and high mechanical strength to weight ratio, and therefore they are used for longer spans with fewer supports and lesser sag at a given tension. ACSR is preferred for it’s capacity to withstand extreme wind loads. Due to the greater diameter of ACSR conductors corona losses are low, resulting in substantial savings in high as well as extra high voltage overhead transmission.

> ACSR conductors have high tensile strength.

> High mechanical strength to weight ratio.

HT power cables

Ashoka Industries specializes in manufacturing XLPE cables ranging from 3300 volts to 33000 volts .

Medium Voltage Cross linked Polyethylene Cables (3.3KV- 33KV)

Cross-linked Polyethylene Insulated XLPE Power Cables possesses excellent electrical, mechanical and heat-resistant properties. It has an advantage over PVC insulated cables because of its easy maintenance,Lighter Weight,Long life,Lasser Electrical Losses etc . ASHOKA INDUSTRIES XLPE cables are manufactured and tested in accordance with IS: 7098 (Part II) and other international standards.

Product Range: - Aluminium/Copper Conductor

- 3.3 kV to 33 kV

- 35 sqmm to 1000 sqmm

- Armoured / Unarmoured

- HT Aerial Bunch Cables

- Strip/wire Armoured Cables

- Single / Multicore Cables

- XLPE; insulation by CCV process & Sioplas process with triple head extrusion.

- Medium Voltage Xlpe Cables have longer life as compared to conventional PVC Cables.

- Medium Voltage XLPE Cables have a higher continuous conductor temperature rating upto 90°C.

- Medium Voltage XLPE Cables have a higher emergency Overload capacity upto 120°C.

- Max. Temperature limit under short circuit conditions for HT-XLPE Cables is 250°C. Hence XLPE Cables have higher short Circuit Rating.

- Insulation Resistance of Medium Voltage XLPE Cable is excellent & superior to identical PVC Cables.

- Medium Voltage XLPE Cables have high corrosion resistance in polluted atmosphere.

- Medium Voltage XLPE Cables have better properties of resistance to chemical and corrosive gases.

- Medium Voltage -XLPE Cables have low installation cost because of light weight dimensions and are far more flexible.

- Medium Voltage -XLPE Cables have better properties to withstand vibrations, hot impacts.

- Jointing of HT-XLPE Cables is easier and quicker.

Ashoka Industries

Ashoka Industries